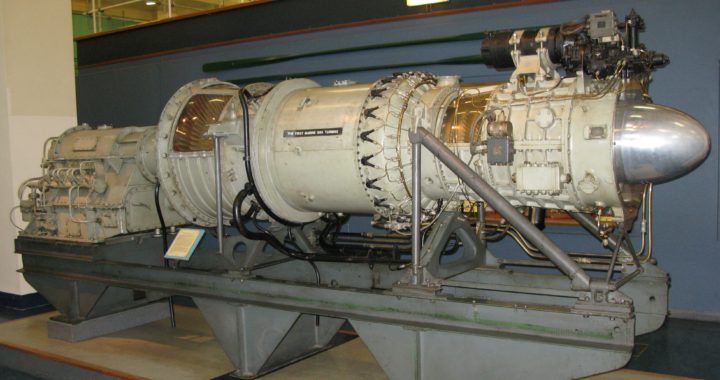

A simple open cycle gas turbine consists of a compressor, combustion chamber and a turbine as shown in the below figure. The compressor takes in ambient fresh air and raises its pressure. Heat is added to the air in the combustion chamber by burning the fuel and raises its temperature.

The heated gases coming out of the combustion chamber are then passed to the turbine where it expands doing mechanical work. Some part of the power developed by the turbine is utilized in driving the compressor and other accessories and remaining is used for power generation. Fresh air enters into the compressor and gases coming out of the turbine are exhausted into the atmosphere, the working medium need to be replaced continuously. This type of cycle is known as open cycle gas turbine plant and is mainly used in majority of gas turbine power plants as it has many inherent advantages.

Advantages:

- Warm-up time: Once the turbine is brought up to the rated speed by the starting motor and the fuel is ignited, the gas turbine will be accelerated from cold start to full load without warm-up time.

- Low weight and size: The weight in kg per kW developed is less.

- Fuels: Almost any hydrocarbon fuel from high-octane gasoline to heavy diesel oils can be used in the combustion chamber.

- Open cycle plants occupies less space compared to close cycle plants.

- The stipulation of a quick start and take-up of load frequently are the points in favor of open cycle plant when the plant is used as peak load plant.

- Component or auxiliary refinements can usually be varied in open cycle gas turbine plant to improve the thermal efficiency and can give the most economical overall cost for the plant load factors and other operating conditions envisaged.

- Open cycle gas turbine power plant, except those having an intercooler, does not need cooling water. Therefore, the plant is independent of cooling medium and becomes self-contained.

Disadvantages:

- The part load efficiency of the open cycle gas turbine plant decreases rapidly as the considerable percentage of power developed by the turbine is used for driving the compressor.

- The system is sensitive to the component efficiency; particularly that of compressor. The open cycle gas turbine plant is sensitive to changes in the atmospheric air temperature, pressure and humidity.

- The open cycle plant has high air rate compared to the closed cycle plants, therefore, it results in increased loss of heat in the exhaust gases and large diameter duct work is needed.

- It is essential that the dust should be prevented from entering into the compressor to decrease erosion and depositions on the blades and passages of the compressor and turbine. So damages their profile. The deposition of the carbon and ash content on the turbine blades is not at all desirable as it reduces the overall efficiency of the open cycle gas turbine plant.