Skip to content

The first step in engineering a breakthrough starts with creating a prototype.

And, because advanced energy solutions today require sophisticated designs and geometries, researchers are increasingly turning to 3D printing to develop those early models. Even the most dexterous hands cannot match the intricate designs from these printers.

At ExxonMobil, technicians in the company’s advanced 3D printing laboratory are forming new acrylic, metal and ceramic spirals and other shapes that are instrumental in larger energy systems.

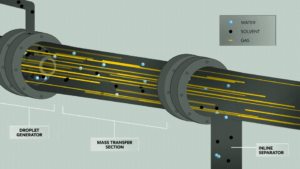

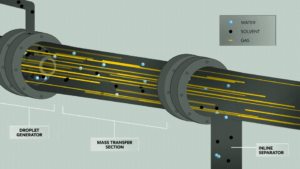

Nothing speaks to this cutting-edge process like 3D printing being used as a rapid prototyping tool for the development of cMIST™ technology. The cMIST system removes impurities like H2O, CO2 and H2S from natural gas production to achieve safety and gas quality standards.

Specifically, the cMIST system has a droplet generator which produces fine droplets of the solvent, well dispersed in the gas, allowing for more efficient processing. These droplet generators start their lives in the 3D printer (as seen below) as prototypes that get tested extensively for performance and reliability.

The 3D printing team was able to quickly roll out models of that cMIST droplet generator, allowing the design engineers to make swift optimizations.

This futuristic printing shop produced an intricate, sophisticated droplet generator. That small piece will be a key component to enable greater production of cleaner-burning natural gas in unconventional reservoirs and challenging offshore deepwater locations.